About Us

Atyaf Alkawn Company specializes in the field of metal fabrication and forming and thermal painting, where we provide our customers with integrated services such as design, supervision, implementation and installation with the highest quality and professionalism stemming from an integrated team with many years of experience in the labor market inside and outside the kingdom of Saudi Arabia. the company has implemented many projects and works for government agencies and private sectors and were delivered to the fullest and to ensure customer satisfaction and meet all their requirements.

Our Vision

Leadership in the field of manufacturing and forming metals, aluminum and paints works

Our mission

Professionalism in providing services with effective tools and specialized modern technologies, managed and supervised by a group of highly qualified experts

Our values

- Excellence and professionalism

- Development and growth

- Customer care

- Collaboration and participation

- Honesty and quality

Services

What We Do

3D DESIGN

Our engineering team designs shapes and metal pieces three-dimensional design in harmony with the required sizes and shape, so that the customer has a clearer view of the final shape

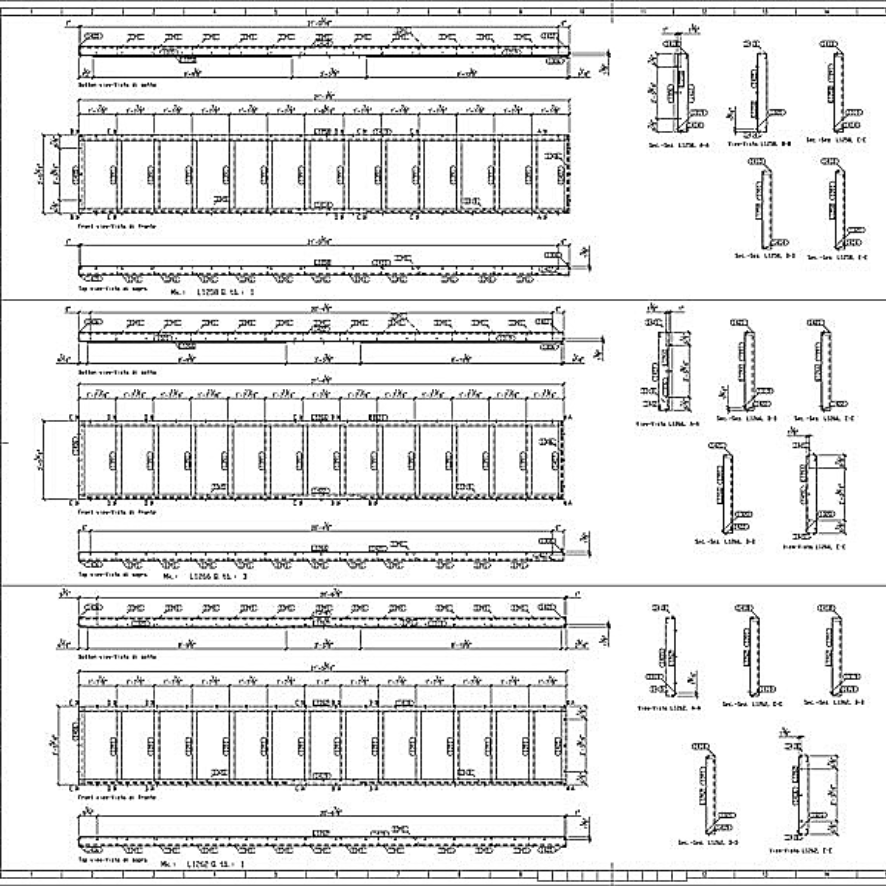

SHOP DRAWING

Our engineering team draws shapes and metal pieces SHOP DRAWING, which are plates showing the dimensions and sizes of the required product until they are baptized by the customer to comply with the data required to work in the final form

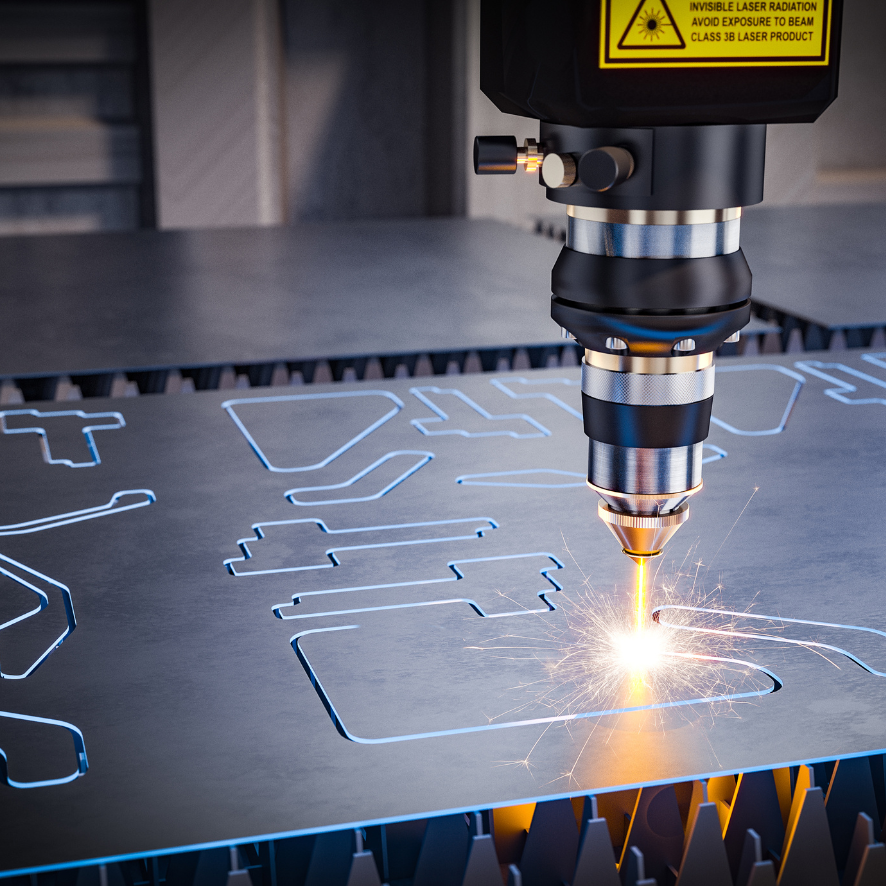

CUTTING

Raw materials must be cut to size. The universe Spectra company has special cutting machines to produce metal shapes according to the appropriate dimensions and straight edges, as the machines are programmed to work according toon the machine.

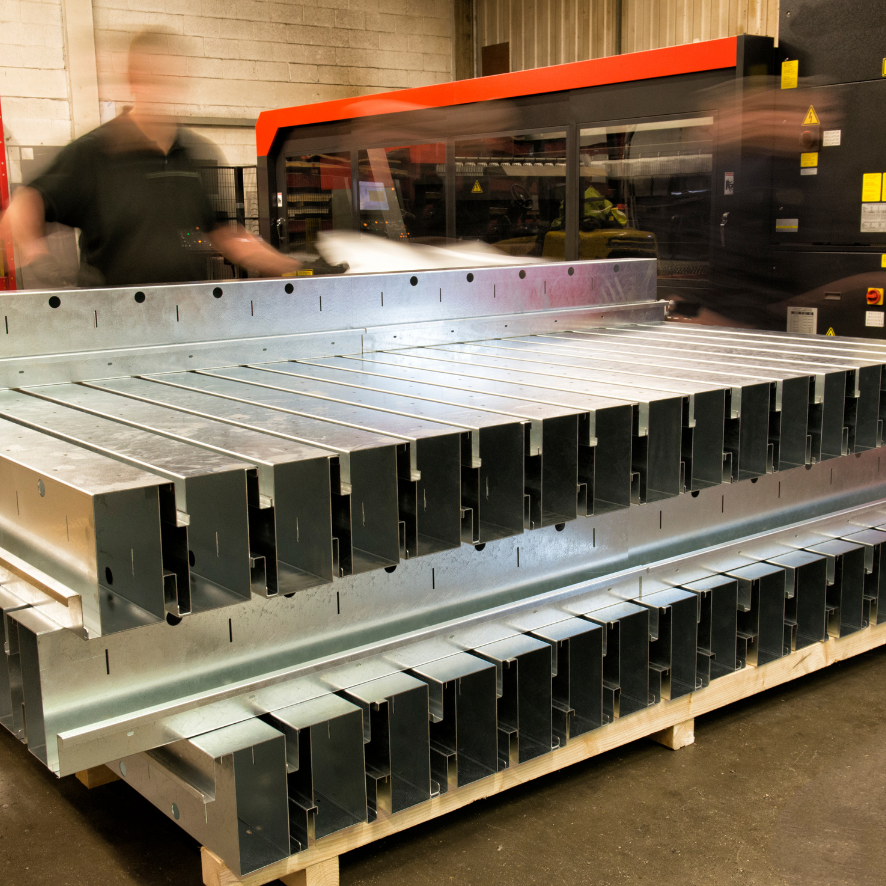

FABRICATION

Forming is the process of deforming raw materials and applying force to them using special machines; in order to shape them according to the required shape according to engineering drawings, and using the appropriate machines and tools produces a model of the metal that can be replicated in a completely consistent manner.

WELDING

The focus is on the manufacturing and forming process at the welding stage until the final shape of the product produces an ideal.

This is done by using advanced special machines and tools and trained staff under engineering supervision, so that the final shape is produced free of defects and traces of welding so that the metal can be re-examined accurately according to engineering drawings.

FINAL ASSEMBLY

After the welding process is completed, the engineering team inspects the product to ensure that it matches the engineering drawings and takes the final baptism from the customer, and then the crew begins to package the product in preparation for shipping, delivery or installation.

Samples of Our Works

Umbrellas

Modern metal umbrellas of all designs according to the customer’s request

Parking shade canopies

Metal awnings protect cars and motorcycles from the sun’s Rays for companies and other large and small enterprises

Lighting poles

Metal lampposts for all needs to suit the design of the place and the intensity of lighting

Metal doors

Metal doors of various types of metals and designs for various needs such as houses and large projects

Hand Railing

Metal handrails of various shapes and decorations as per customer’s request

Solid bollards

Solid poles according to the desired shape of various types of stainless metal are

Fencing and barriers

Metal fences with or without concrete barriers are designed according to the endurance of the barrier and the required endurance

Metal Rails

Metal road rails for the protection of stray cars on the road or people with parameters that match traffic engineering

Industrial ladders

Circular and straight metal ladders of various metals such as steel to be manufactured with high flexibility according to the required design

Metal facades

Metal facades for curtain and decoration, manufactured and designed according to the needs of the place to beautify the facade or cover existing works

HOARDINGS

A metal fence for projects in cooperation with the spectra of the universe company with authorized advertising agents

Solid structures

Solid metal structures for projects, supply hangars and scaffolding with the availability of all the necessary capabilities and equipment to complete the project

Observation towers

Tailoring and shaping of metal structures of observation towers according to the required design and parameters

Pipe Shoes and saddles

We provide a full range of saddle and pipe supports with standards commensurate with the customer’s request of materials up to the required temperature tolerance

Decorative facades

Metal facades for curtain and decoration, manufactured and designed according to the needs of the place to beautify the facade or cover existing works